The Famous Drum Company creates professional level drums that are unique, specialty designer instruments. They are of the highest sound quality and use beautiful woods finished with oil or water based lacquer, and Delmar plastic finishes. All of the drums have unique construction qualities which are not seen in other drums. The in-house shells are made in our woodworking shop run by Evan Thomas in Phoenix Arizona. The finishing, drilling, assembly, and tuning are done in George Lawrence’s work shop in Memphis Tennessee. To order or to be included in the “audition tour” please contact George Lawrence at george@notsomoderndrummer.com or 330 338 6035. Famous Drum single ply shells for drum builders are listed for sale at www.DrumSellers.com

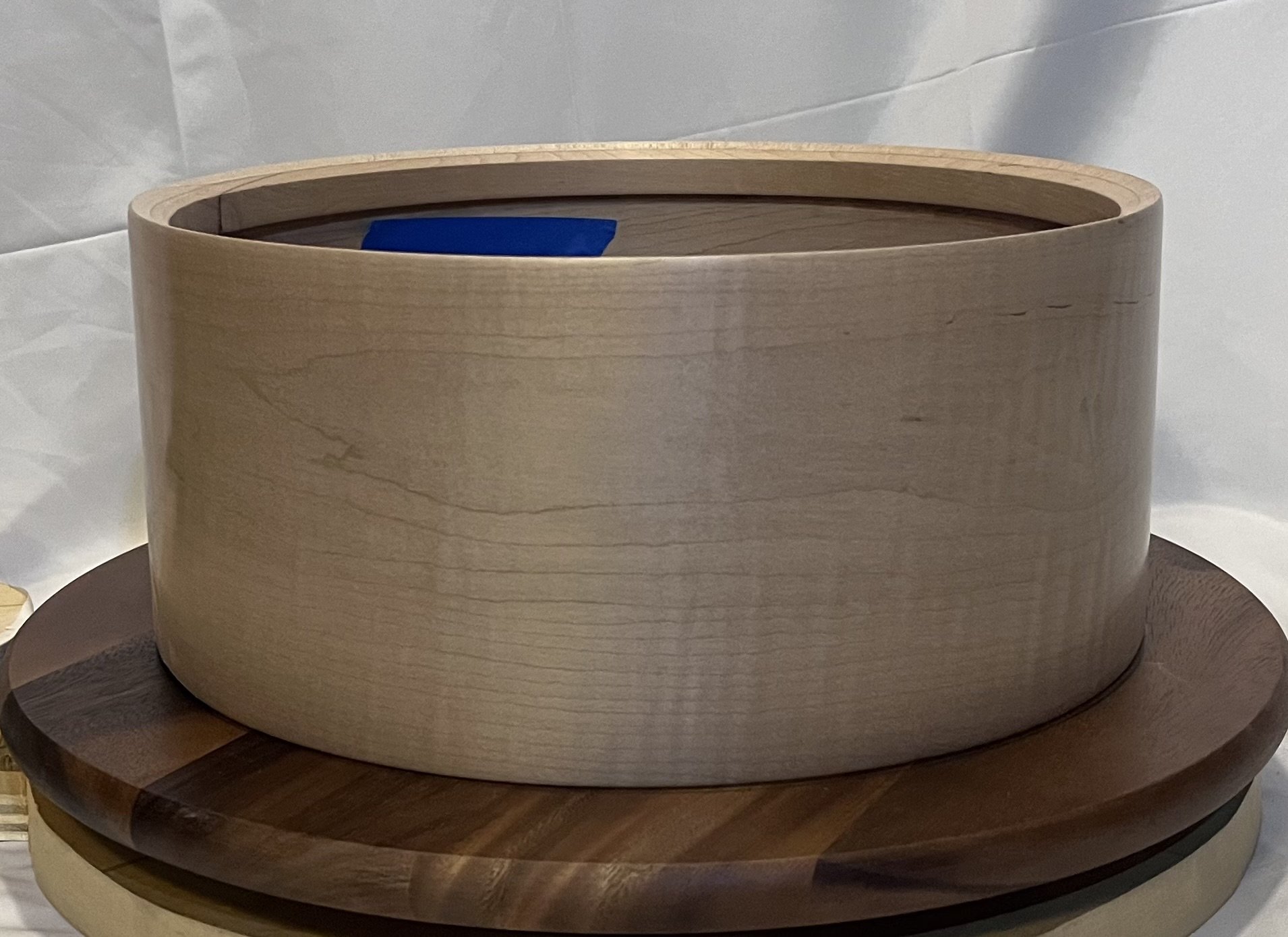

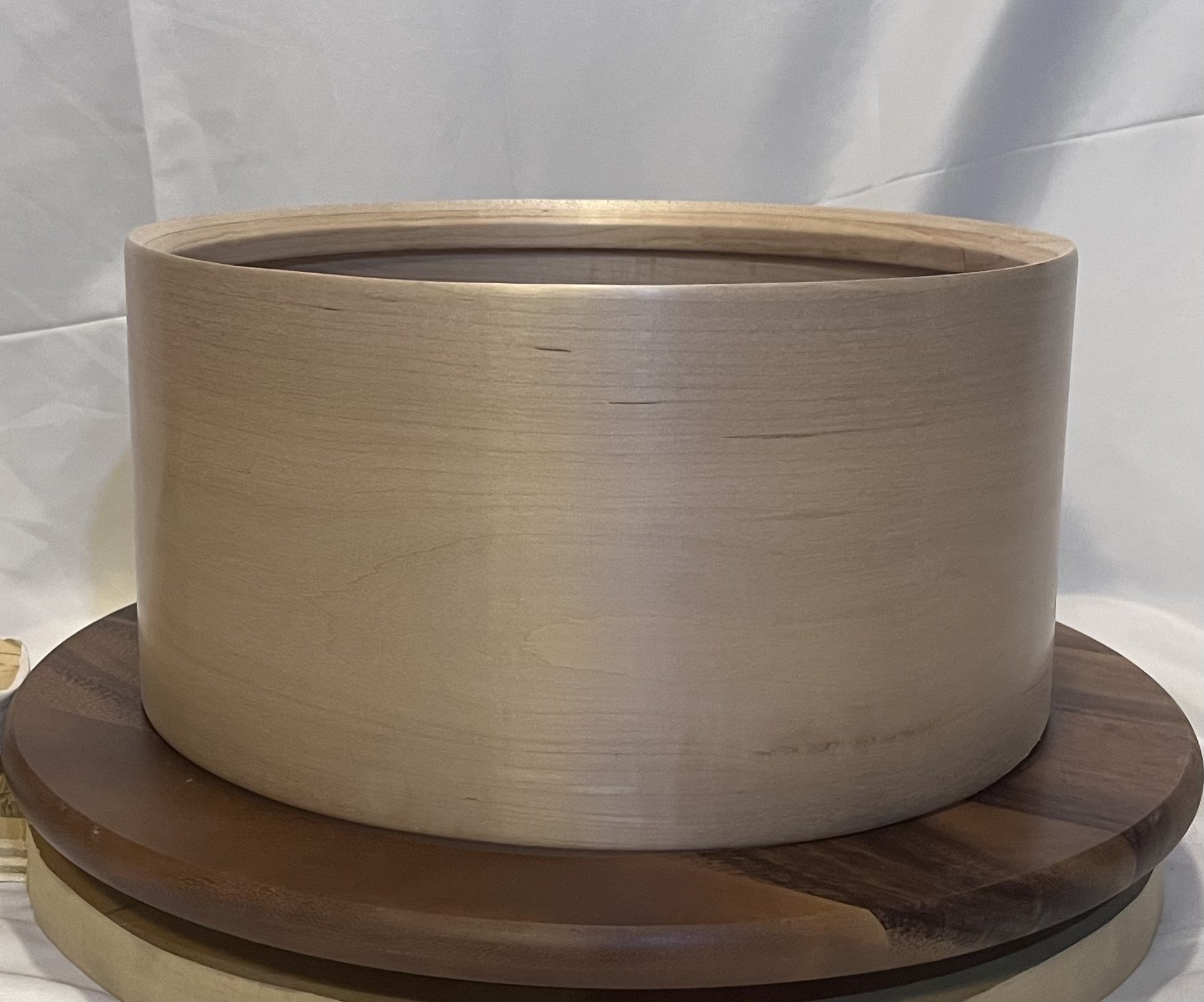

Above - raw shells, single ply steam bent with reinforcement rings. See our available stock at DrumSellers.com or contact us for made to order shells - all woods all sizes.

The Solid 10 Celebrity Model

The exclusive single ply steam bent maple shell is hand made in our woodworking shop in Phoenix Arizona. The unique features on the 7.25” x 14” curly maple model shown include ten vintage Slingerland Radio King style beavertail 3.5” lugs, ten hole chrome over brass 2.3 mm counter hoops, and an extended snare wires and strainer system with dual tensioning that allows for maximum snare sensitivity and response. This drum’s shell is an exact replica of the vintage single ply shells of the past in its deep, wide snare beds, the thickness of the shell and the dimensions of the reinforcing rings at top and bottom.

.

The Solid 8 Model

While this is our simplest single ply model, it is elegant in its design. The single ply, steam bent shell is hand made by E.T. in our Phoenix Arizona work shop. The eight lugs are vintage style beavertails. The dual tension strainer system has a side to side lever throw off and a matching butt. Hoops are 2.3 eight hole chrome over steel triple flange.

The Block 8 “2x4” Model

The 2x4 is made from Spruce lumber with block construction. The lumber is cut into small blocks, glued together, then turned on a lathe. The shell is rather thick which contributes to its large sound. Joe Partridge designed this drum. Parts include 2.3 mm chrome over steel counter hoops, 8 Sound Kind stye lugs, and several different optional snare throw off/butt/snare wire systems (the one shown is no longer available).

The Tone Ring

The concept of the tone ring was inspired by a similar device used by Slingerland in the early part of last century, a metal ring that attached to the top of the wood shell and sat just underneath the drum head to produce a “pizzicato” effect. The Famous Tone Ring is a patented device that is mounted to the inside of the shell and mutes the ringing of the outer inches of the drum head. While it is an inner muffler that does not touch the head, the tone ring also strengthens the shell. It makes it more rigid which raises the pitch of the end of the shell and creates a rich sound. There is also an optional full wood ring which sits on top of the “holy” ring shown which completely deadens the head. This design was a collaboration between Joe Partridge and George Lawrence.

The Components

We use only the best components available, selecting each for how it contributes to the sound of a specific model drum.

And, below, a gallery of drum models we have built in the past, raw shells, Evan and Joe.

Famous Artist Bill Ray thoroughly demonstrating the Famous 2x4 snare. Bill has recorded and toured with a number of recording artists from the West Coast, the most notable being Ike Turner for many years.

This was the first Famous steam-bent single-ply snare drum, circa 2009. I wish I had never sold it. This quickie camera demo was done for the customer who bought it. I was calling it the “Fat Boy” in this video, but the actual current model name is the Classic. - George Lawrence

The first of three videos documenting the process that drum maker Evan Thomas developed several years ago at his first “factory” (the front porch of his trailer). He has since moved into the new indoor factory. He will be re-making these videos soon because the process and tooling has been improved and refined over the last few years. stay tuned