The Chicago Drum show in May was all I expected it to be. My only problem was I didn't have enough time to really dig in and see everything. My wife and I drove to our son and daughter-in-law's home in Charlotte on Friday. It was hard to sleep Friday night. I was extremely excited about going to the show on Saturday. My son and I started out early Saturday morning with a flight to Chicago. We rented a car and drove out to St. Charles to the fairgrounds where the show is held. I thought I would have plenty of time to see everything and visit with friends. There was so much to see and it was time to catch a plane back to Charlotte before I knew it. If I get to go back next year I will definitely plan to have more time. There were so many people there I wanted to talk to, and if I didn't get to speak to you, I'm sorry. I highly recommend that you go to a vintage drum show if you possibly can. Watch for announcements in the magazine for shows around the country.

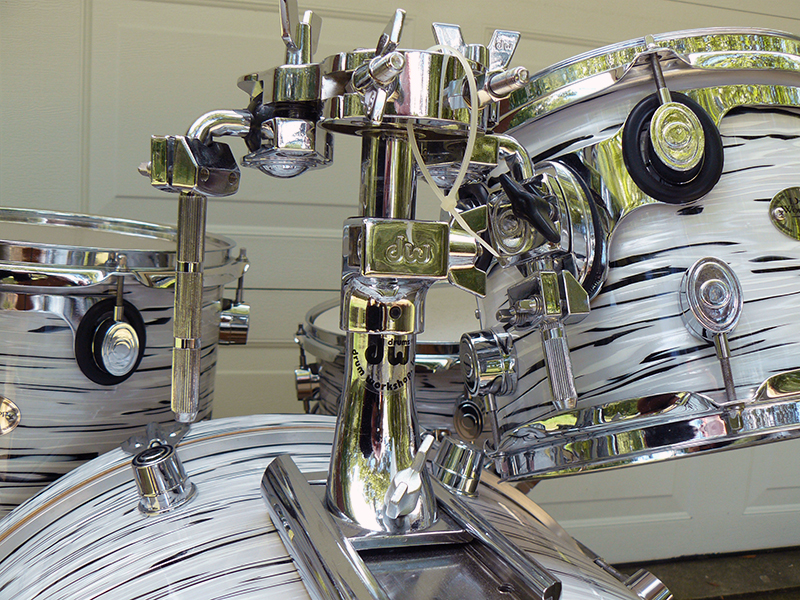

The drum kit I want to feature this month is a beautiful set built by Drum Workshop. I know you are all familiar with the awesome drums this great drum company is making. The Collector Series is the flagship drums of Drum Workshop. They have the Aristocrat lugs like the ones made popular by George Way and Camco drums. Drum Workshop is built on the foundation of Way and Camco. The Workshop Series line of drums was the company's first attempt at a second line of drums. It was a set that was offered to the working and hobby drummer at a slightly better price, but still very high quality in every way. The most noticeable difference was the oval lugs instead of the round lugs. Another difference not so noticeable was the thin Keller shells without reinforcement rings. These drums sound fantastic. The first Workshop Series drums were limited in colors and sizes. That soon was scrapped because there were special orders for Workshop Series drums in special sizes and wraps. Drum Workshop officially only made the Workshops a couple of years, but continued to make them for special orders for quite some time.

The following information was gleaned from a drummer's forum. There was no name given, so I can't give proper credit. The facts are good and answers a lot of questions about these great drums.

BACKGROUND INFO ON THE DW WORKSHOP SERIES LINE:

"My drums are DW Workshop Series, made in the U.S. in 2000. There is much confusion surrounding this somewhat-rare line offered by DW.

I have read a lot of messages of people inquiring about DW Workshop series drums with most replies having bits and pieces of truth with some personal opinions thrown in. Lots of readers want to know about their quality and their price range. The Workshop series for the record were indeed 100% DW drums. They were manufactured in the USA (Oxnard), contrary to what some people have been stating. They were never made in Ensenada, Mexico. They were manufactured with what resembles the PDP lug to distinguish them from the Collector series.

They were built for only two years. They were made without reinforcement hoops, and were meant to be DW's good, mid-range product. Since they were just as expensive to manufacture as DW's Collector's Series, they were discontinued. Apart from that, they were favored by many DW endorsers in spite of the Collector's series.

They were DW's first go at manufacturing an American made "mass produced" set. They didn't offer the custom features like timbre matching and had limited finishes. The finishes were a high-gloss lacquered all-maple shell, or a Satin-Oil all-maple shell. The drums, aside from the different lugs, garnished authentic DW hardware as in the snare strainer. bass drum spurs and tom mounts. Again, 100% DW. DW dropped this line after about 2 years in production because they became too costly to produce, rivaling the production costs of their collector series, but they didn't carry the same retail price tag.

So with that, the line was scrapped in favor of the Pacific line. With the technology they gained making the Workshop series, they started to produce the PDP's in Taiwan. Pacific’s were not originally manufactured in Ensenada. DW chose to move the PDP line to Ensenada in the mid 90's to keep the costs down on the shipping tariffs from overseas and to be closer to the factory for quality control. But to state it one more time, the Workshop series was an American manufactured all-maple set. The sound is impeccable and they do not have the reinforcement ring for a broader sound, something DW is now offering (priced) on their Collector series sets. All the Workshop series drums have a DW badge with a serial number stamped on each shell stating "Made in the USA."

The Bottom Line Facts: These drums were "Made in the USA", with the same quality maple and parts that go into the Collector's Series drums. The only difference- apart from the differently-shaped lug housings, is that these have no reinforcement hoops. This difference is said to give them more sustain and a more open tone. I completely agree. I didn't buy these because they were less than the Collector Series: they just sounded better, more open, to me."

The toms on this kit I am featuring has a 10", 12" and 15" configuration. The bass drum is a thunderous 22"X18". The matching 14"X5" snare is also a very nice touch for this set. This set was obviously a special order and not a standard Workshop Series Kit. The tom sizes and the Ultra White Oyster wrap clearly had to be ordered. If you have a set of Workshop Series drums please comment. I live for your comments.

Hope you have a great Summer.